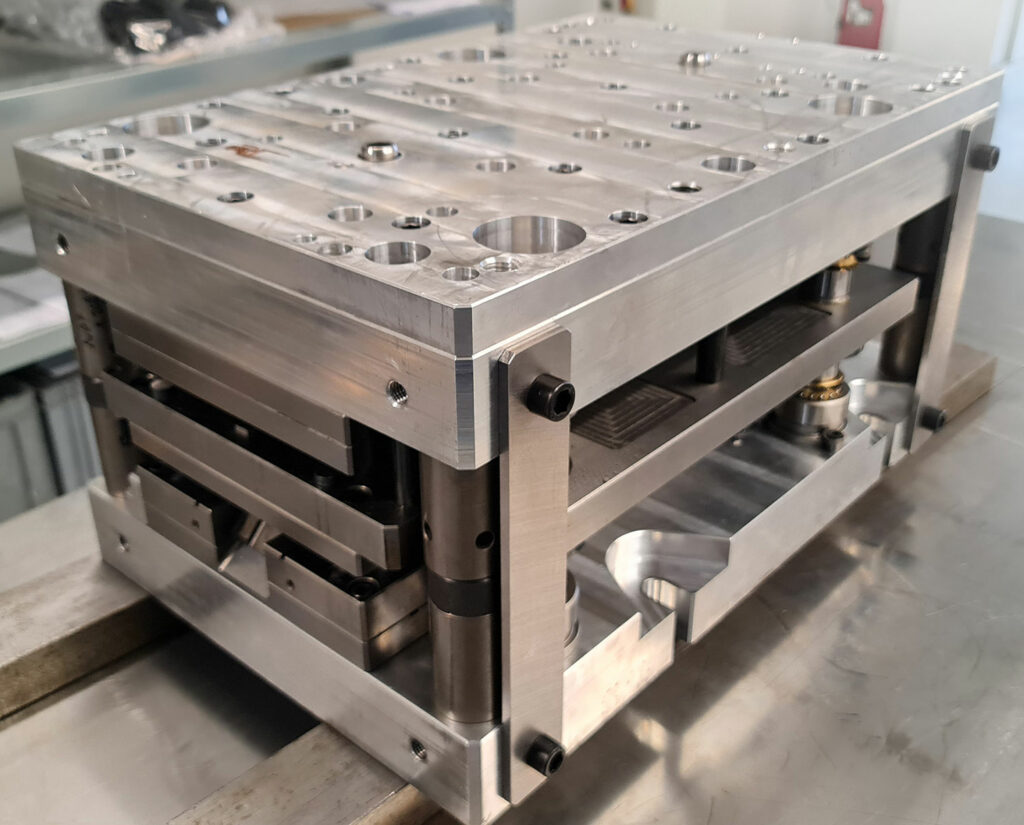

We produce precise and accurate tools – cutting, bending, combination and modular. In addition, our portfolio includes moulds for plastic injection moulding, assembly and single-purpose jigs and parts for cutting tools and forms. Last but not least, we also design single-purpose automatic and manual assembly stations.

In addition, we provide comprehensive service and professional maintenance – especially of cutting and bending tools and moulds for plastic injection moulding – which makes us a long-term valuable partner for our clients.